IRDS internally fed rotary drum screen is the equipment for medium flow, medium low solid rate wastewater. It is compact sized, completely closed and low malfunction machine, which is solid-liquid separation device for normal wastewater. The cuneal or punched type filter can be choose with the machine, the most common aperture is 0.25~6mm.

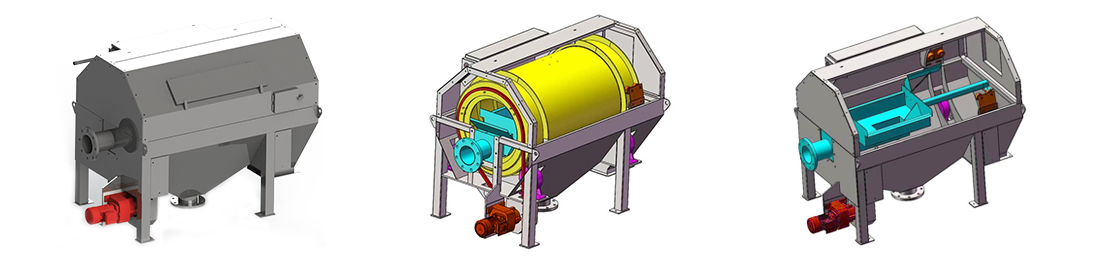

PRODUCT STRUCTURE:

The drum screen is supported by four rotating wheels, and the horizontal rotation is driven by TEFC reducer, roller chain and sprocket. The spray system is automatically sprayed with water. The one piece structuredesign, solid structure, the high quality stainless steel materials, to ensure that the equipment can long-term trouble-free operation, low energy consumption simple maintenance, reduce the process after the processing load.

APPLICATIONS:

Municipal Sewage treatment,Papermaking wastewater,Water Treatment Plant,Leather industry,Beverage industry,Slaughterhouse,Pharmaceutical wastewater,Food industry,Petrochemical industry.

PRODUCT FEATURE:

1.SS304 stainless steel member;

2.One piece structure;

3.TEFC drive system;

4.Anti-corrosion roller chain;

5.Cylindrical roller bearing and UHMWPE wheel assembly;

6.Screw blade;

7.External spray system;

8.Sealing cover plate;

9.Design of drain pan and slagging discharge;

1.Efficient filtration

The filter screen of the internal circulation drum grille cleaning machine has high filtration accuracy, which can effectively remove suspended solids, fibers, hair and other impurities with smaller particle sizes in sewage, greatly improving the quality of sewage treatment.

2.High degree of automation

The equipment is equipped with advanced control systems that can achieve functions such as automatic operation, automatic flushing, and automatic slag discharge, reducing the workload of manual operation, lowering labor intensity, and improving the stability and reliability of equipment operation.

3.Stable operation

The drum adopts a special design and manufacturing process, which rotates smoothly and is not prone to problems such as jamming and vibration. Moreover, the various components of the equipment are closely coordinated and can operate stably for a long time in harsh working environments.

4.Small footprint

Compared to some traditional grid cleaning equipment, the internal circulation drum grid cleaning machine has a compact structure and a small footprint, making it particularly suitable for use in sewage treatment plants with limited space.

5.Easy maintenance

The various components of the equipment are designed reasonably, easy to disassemble and install, and convenient for daily maintenance and upkeep. Moreover, the flushing system can effectively prevent filter clogging, reduce the frequency of filter replacement, and lower maintenance costs.

| Serviceable Range | Solt | IRDS-3036(m³/h) | IRDS-3048(m³/h) | IRDS-S3060(m³/h) | IRDS-4248(m³/h) | IRDS-4272(m³/h) | IRDS-5472(m³/h) | IRDS-5496(m³/h) |

| Dimensions Of Screen | mm | φ800x950 | φ800x1220 | φ800x1524 | φ1060x1200 | φ1060x1830 | φ1380x1830 | φ1380x2440 |

| Municipal Sewage | 2.5 | 136 | 182 | 227 | 318 | 455 | 636 | 818 |

| Paper Industry | 0.1 | 30 | 41 | 52 | 68 | 102 | 145 | 193 |

| Paper Industry | 0.8 | 72 | 80 | 95 | 125 | 193 | 273 | 364 |

| Paper Industry | 1 | 73 | 103 | 127 | 159 | 227 | 386 | 500 |

| Fruit And Vegetable Industry | 0.5 | 68 | 91 | 114 | 148 | 216 | 318 | 341 |

| Fruit And Vegetable Industry | 0.8 | 73 | 95 | 118 | 180 | 227 | 455 | 477 |

| Seafood Industry | 0.5 | 55 | 73 | 95 | 125 | 193 | 296 | 382 |

| Seafood Industry | 0.8 | 59 | 80 | 102 | 136 | 205 | 318 | 421 |

| Meat Industry | 0.5 | 55 | 73 | 95 | 125 | 193 | 296 | 386 |

| Meat Industry | 0.8 | 59 | 80 | 102 | 136 | 205 | 318 | 421 |

| Poultry Industry | 0.5 | 55 | 73 | 95 | 125 | 193 | 296 | 386 |

| Dimensions(LxWxH) | m | 2.1x1.2x1.4 | 2.4x1.2x1.4 | 2.7x1.2x1.4 | 2.5x1.5x1.8 | 3.1x1.5x1.8 | 3.1x1.8x2.3 | 3.7x1.8x2.3 |

| Influent Flange | DIN | DN150 | DN150 | DN150 | DN200 | DN200 | DN300 | DN300 |

| Effluent Flange | DIN | DN150 | DN150 | DN150 | DN250 | DN250 | DN400 | DN400 |

| Spray Influent | G | G1-1/4" | G1-1/4" | G1-1/4" | G1-1/4" | G1-1/4" | G1-1/4" | G1-1/4" |

| Solids Discharge | mm | 254x305 | 254x305 | 254x305 | 254x457 | 254x457 | 254x610 | 254x610 |

| Dry Weight | kg | 500 | 590 | 720 | 680 | 1020 | 1700 | 2250 |

| Wet Weight | kg | 720 | 810 | 950 | 1050 | 1500 | 2000 | 2800 |

| Power | kw | 0.37 | 0.37 | 0.37 | 0.55 | 0.75 | 1.1 | 1.1 |