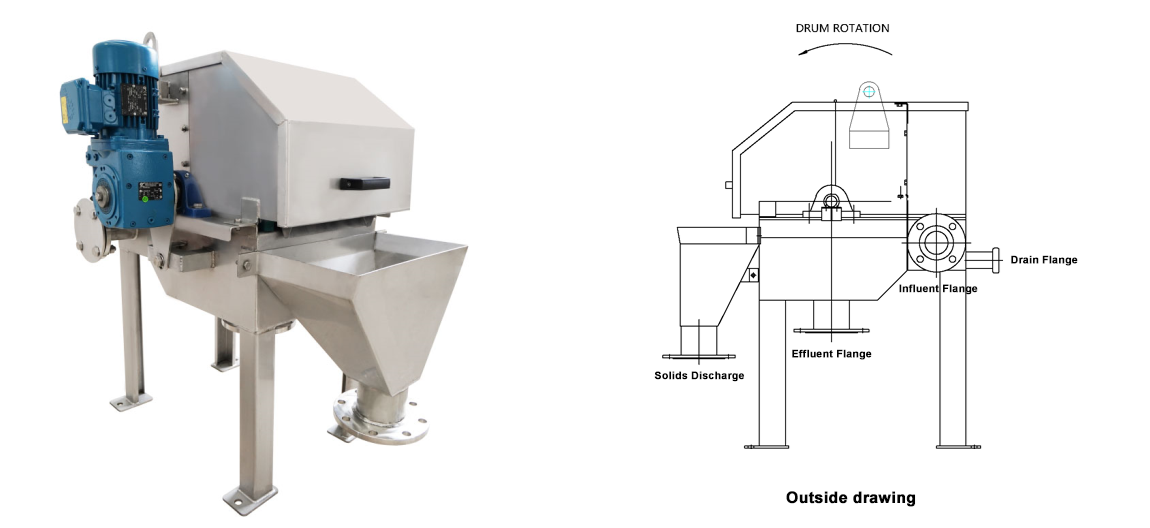

RDS series drum screen mainly focus on the medium flow rate, low and medium solids rate of sewage; which is Is a compact structure, completely closed and low failure rate model, and to solve common sewage solid-liquid separation equipment. The screen can be wedge-shaped screen and perforated screen, the common aperture is 0.25~6mm.

WORKING PRINCIPLE:

The suspended matter in the sewage retained on the rotating drum, and with the rotation of the drum, it is sent to the discharging end of the other side from the inlet end, which is shoveled down by the unloading device. The time relay in control cabinet controls the back flush solenoid valve to open and close periodically so that to clean the blockage between the drum bars. The integral design, strong construction and high quality stainless steel material ensure the equipment can long-term operate with trouble-free and low energy consumption. Simple maintenance.

PRODUCT FEATURE:

1.SS304 stainless steel member;

2.Integral structure;

3.External spray system;

4.Sealing cover plate;

5.Frequency control range 4-20 rpm;

6.Automatic blow slag;

7.Timed back flush.

| Serviceable range | Solt | RDS03/300(m³/h) | RDS06/400(m³/h) | RDS06/700(m³/h) | RDS06/1000(m³/h) | RDS06/1300(m³/h) | RDS06/1600(m³/h) | RDS06/2000(m³/h) | RDS08/2000(m³/h) | RDS08/2500(m³/h) |

| Size | mm | φ3000X300 | φ610X400 | φ610X700 | φ610X1000 | φ610X1300 | φ610X1600 | φ610X200 | φ610X2000 | φ610X2500 |

| Municipal sewage | 1 | N/A | 60 | 100 | 150 | 200 | 240 | 300 | 450 | 560 |

| Paper industry | 0.5 | 6 | 20 | 35 | 50 | 65 | 80 | 100 | 150 | 185 |

| Seafood industry | 0.75 | 5 | 17 | 30 | 42 | 55 | 68 | 85 | 125 | 160 |

| Meat industry | 0.5 | 4 | 15 | 25 | 38 | 50 | 60 | 75 | 110 | 135 |

| Meat industry | 0.75 | 6 | 20 | 35 | 50 | 65 | 80 | 100 | 150 | 185 |

| Meat industry | 1 | 7.5 | 25 | 45 | 62 | 83 | 100 | 125 | 185 | 235 |

| Fruit and vegetableindustry | 1 | 12 | 40 | 70 | 100 | 100 | 160 | 200 | 300 | 375 |

| Driving power | kw | 0.18 | 0.37 | 0.55 | 0.75 | 1.1 | ||||

| Output speed | rpm | 18 | 10 | |||||||

| Length (L) | mm | 860 | 1000 | 1300 | 1600 | 1900 | 2200 | 2600 | 2650 | 3100 |

| width (W) | mm | 1020 | 1520 | 1680 | ||||||

| Height (H) | mm | 1050 | 1600 | 1950 | ||||||

| Water out height | mm | 350 | 500 | 650 | ||||||

| Water inlet flange | DIN | DN65 | DN80 | DN100 | DN150 | DN120 | DN250 | |||

| Water outlet flange | DIN | DN100 | DN150 | DN200 | DN250 | 2xDN200 | ||||

| Back wash nozzle | G | G1/2" | ||||||||

| Vent nozzle | 3A | φ2" | ||||||||

| Slag notch | DIN | DN100 | DN150 | 2xDN150 | ||||||

| Net weight | kg | 41 | 76 | 95 | 109 | 123 | 142 | 164 | 205 | 245 |

| Operating weight | kg | 68 | 136 | 164 | 196 | 232 | 273 | 327 | 409 | 491 |