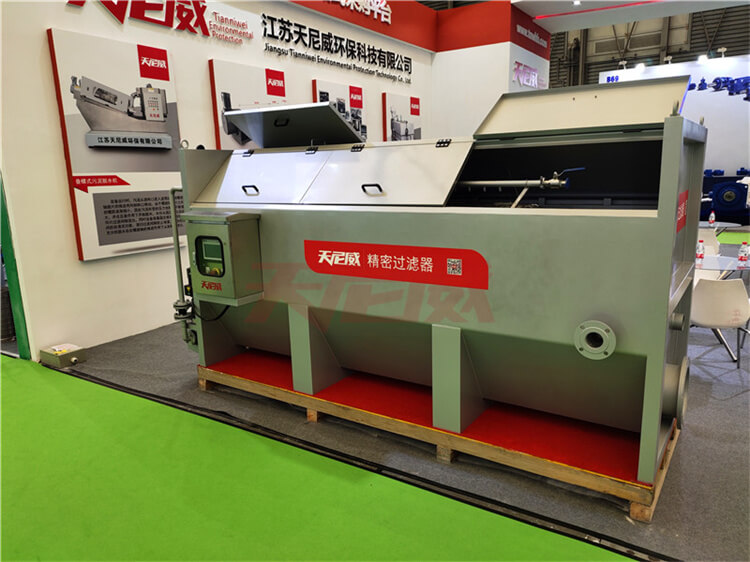

Maintenance of rotary drum precision filter

Maintenance of rotary drum precision filter

1. When the precision filter works for a period of time, the filter element blocks a specific amount of impurities. At this time, the pressure drop will increase, and the flow rate will decrease. The impurities in the filter should be removed in time, and the filter element should be cleaned at the same time;

2. Some precision filter elements cannot be used repeatedly, such as bag filter elements, polypropylene filter elements, etc;

3. When removing impurities, especially the precision filter element, it shall not be deformed or damaged, otherwise, the purity of the filter element after filtering will not meet the design requirements;

4. The core part of the precision filter is the filter element. The filter element is made of special materials, which is suitable for damage and needs special protection;

5. If the filter element is deformed or damaged, replace it.

During the installation and use of the precision filter, if you can pay attention to the application methods, you can extend the service life of the product and meet the purpose of reducing costs. In addition, users can regularly check the equipment when using it, so that they can know the application status of the product in time, adjust any problems they find, and make filtering easier and reduce the probability of failure.

During the use of precision filters, attention should be paid to the setting of products. In fact, compared with ordinary products, this kind of equipment will perform better in terms of filtering effect during operation. Therefore, it has high strength during application and can also operate continuously, providing more convenient conditions for filtering operation. If the equipment is installed and applied for a long time, it is prone to some losses, which will affect the working state of the product. Therefore, when using the equipment for filtering, you can first determine the filtering amount, which can reduce the burden of the equipment and also meet the ideal application effect.

It is also important to clean and maintain the precision filter regularly. If the equipment is cleaned and maintained in time, the service life of the product can also be extended in some cases. If users do not need to use the equipment and products within a specific time, they need to clean the products, which can avoid the retention of impurities and waste, and also avoid the impact of stains on the products. During the use of the product, attention should be paid to these problems, so that the longer the application time of the precision filter is, the better it can be maintained, and the more cost can be reduced for users.

Now, the application scope of rotary drum precision filter is very wide. Because of the greater progress in design and process, it has also been praised by users during the actual application. The product can be used in the pharmaceutical industry and food processing sites for installation and use. In addition, it is also widely used in the field of environmental protection.