Development and Application of Multi disk Screw Press

Development and Application of Multi disk Screw Press

Screw filter, also known as screw squeeze dehydrator, first appeared in Germany in the 1960s, followed by the former Soviet Union, Sweden, the United States and other countries to manufacture this type of filter, and was first used in oil pressing and meat crushing dehydration after fish meat grinding, fish and shrimp waste filtration, in recent years, it has been widely used in sludge dehydration and other industrial process dehydration fields.

Why did you choose multi disk screw press?

Sludge is an inevitable product of sewage treatment in sewage treatment plants and sewage stations. After entering the environment, sludge that has not been well treated and disposed will directly cause secondary pollution to the water and atmosphere, posing a serious threat to the ecological environment and human activities. Therefore, sludge treatment is very cautious. Sludge treatment can be divided into two types: sludge dehydrator process and sludge drying process. The main product of sludge dehydrator is multi disk screw press.

What are the advantages of multi disk screw press?

Multi disk screw press is a water treatment system widely used in municipal sewage treatment projects and industrial industries.

Small design

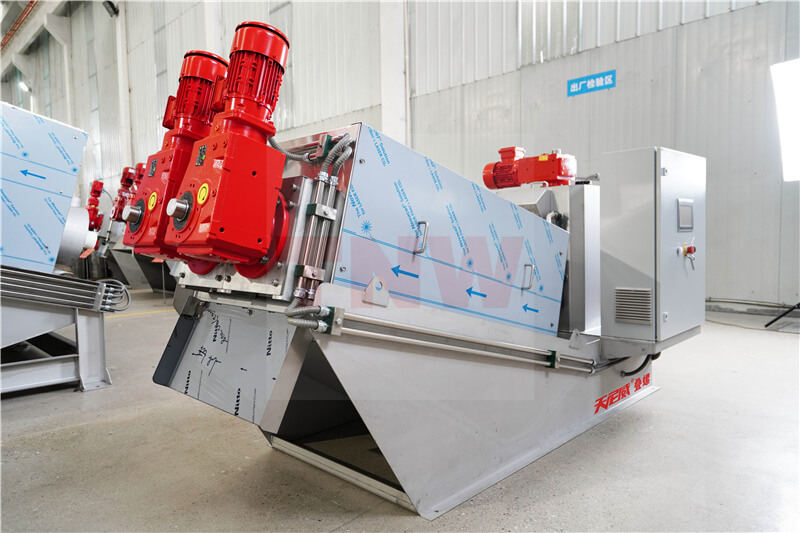

1. Compact design, the dehydrator includes electric control cabinet, metering tank, flocculation mixing tank and the main body of the dehydrator.

2. Small floor space, convenient for maintenance and replacement; Small weight, convenient for handling.

Not easy to block

1. It has self-cleaning function. It is not necessary to clean the filter to prevent clogging of the filter seam. The water consumption for flushing should be reduced to reduce the burden of internal circulation.

2. Be good at dewatering oily sludge.

Low speed operation

1. The rotating speed of the spiral shaft is about 2~3 rpm, and the power consumption is extremely low.

2. Less faults, less noise and vibration, and safe operation.

Durable

1. The body is almost made of stainless steel, which can maximize the service life.

2. Only the spiral shaft and traveling ring are replaced, with a long service life.

Multi disk screw press is mainly applicable to the following aspects:

1. It is applicable to sludge in municipal sewage, food, beverage, chemical industry, leather, welding materials, papermaking, printing and dyeing, pharmaceutical and other industries.

2. It is suitable for dehydration of high and low concentration sludge. When dewatering sludge with low concentration (2000mg/L~), there is no need to build thickener and storage tank to reduce construction cost, phosphorus release and anaerobic odor generation.