Operating cost of sludge dewatering press

Sludge dewatering press is very popular in the field of solid-liquid separation. Is the operation and maintenance cost of sludge dewatering press a big problem?

1. The construction cost of sludge dewatering press is very low

No concentration tank is required, and the design is adapted to local conditions to reduce the capital construction cost and greatly reduce the floor area.

2. The design cost of sludge dewatering press is low

The model and specification are very mature. According to the processing capacity, a relatively standard drawing can be produced, which can basically be regarded as a standard part.

3. Low maintenance cost of sludge dewatering press

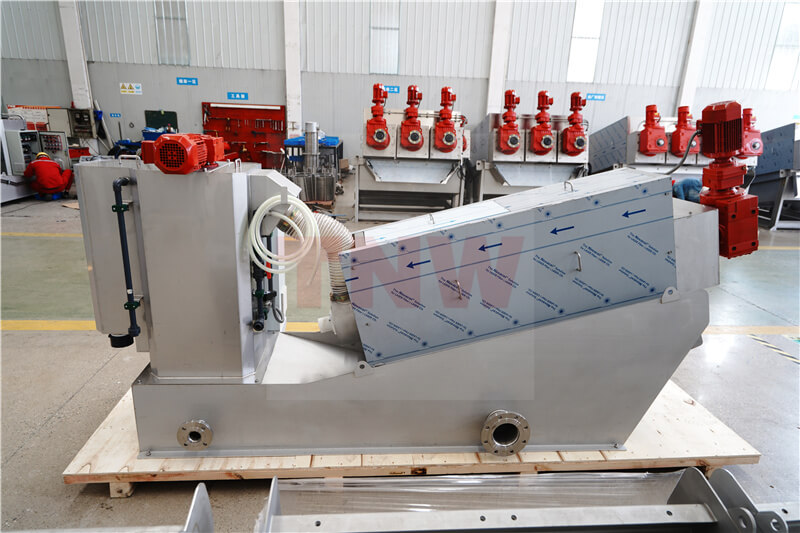

The main body of the dehydrator has self-cleaning function, so it does not need a large number of people to clean it to prevent sludge blockage. Low speed screw extrusion technology, low power consumption.

The electric control cabinet is equipped with an automatic control device, which can realize 24-hour automatic continuous unmanned operation from sludge conveying, liquid medicine injection, thickening and dewatering to sludge cake discharge, reducing the labor cost.

for instance:

Project type: municipal sewage treatment plant

Processing capacity: 30000 t/d

Sludge output: 400 m3/d

Water content of sludge:~99.2%

Absolute dry sludge volume: 3.2 t-DS/d

Water content of sludge: ~ 80%

Running time: 20h/d

Annual running time: 320 days

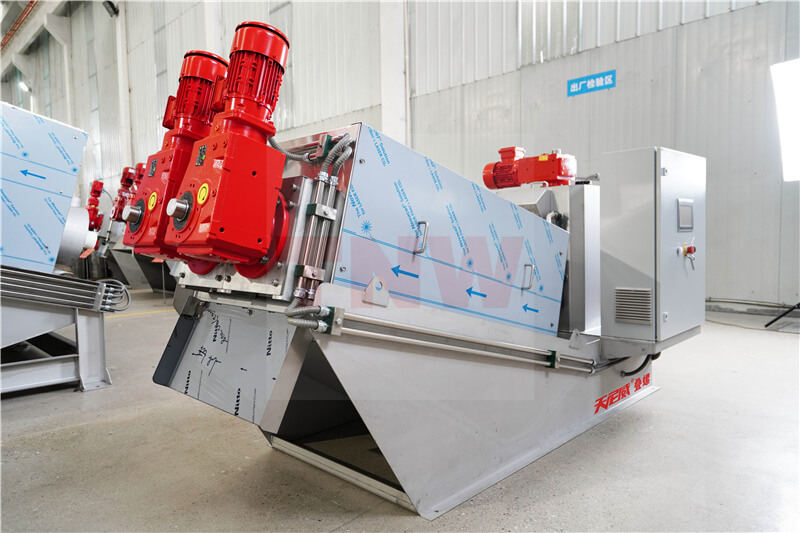

According to the situation of this project, the equipment is a belt type thickening and dewatering integrated machine with a bandwidth of 2 meters, with a host power of 10.25kw, or a TNW303 screw type sludge dehydrator with a power of 2.25kw.

According to the condition that the daily treatment capacity and dewatering effect are the same, the water consumption and power consumption of the screw type sludge dehydrator are the lowest, and the labor cost can be reduced, and the overall operating cost is the lowest.

If the residual sludge with a moisture content of 99.2% of 400m3/d is treated every day and 320 days are worked every year, if the tap water is used as the backwash water of the belt type machine, the sludge dewatering press can save 338800 yuan annually compared with the belt type machine, and the equipment investment cost can be recovered within half a year.

Through the above simple analysis, we may have a certain understanding of the operation and maintenance costs of the sludge dewatering press.

PRE : Reasons for high water content of sludge dewatering press