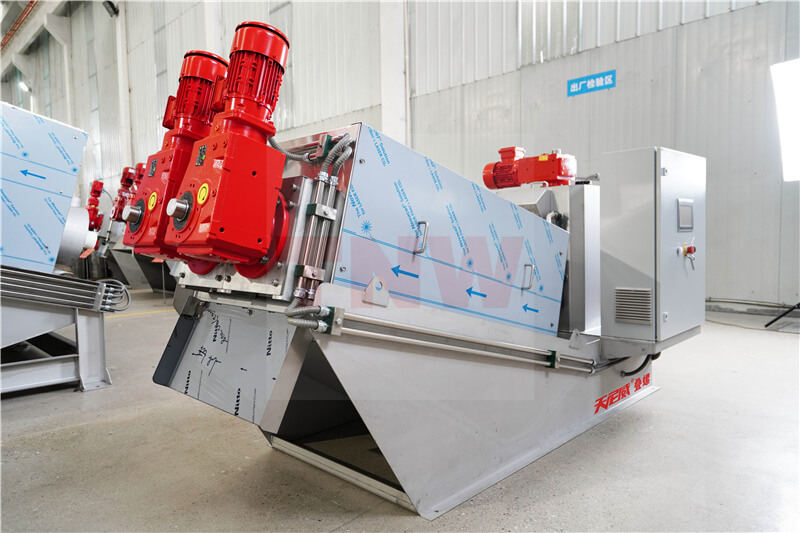

Sludge dewatering press for kitchen waste water treatment

Characteristics of kitchen waste water:

In the process of stacking and treatment of kitchen waste, a kind of wastewater with high concentration of organic or inorganic components is produced due to biochemical degradation such as compaction and fermentation. The sewage has complex components, high pollutant concentration, extremely unpleasant odor, and extremely unstable sewage quality. Compared with the sewage quality of urban pipe network, its main pollutant indicators exceed many. If it is directly discharged into the urban pipe network, it will cause impact on the sewage treatment plant and affect the stable operation of the sewage treatment plant.

Kitchen waste water generation:

Kitchen waste water is produced by the catering industry. The development of the catering industry has brought a large amount of kitchen waste water. For food safety, kitchen waste cannot be directly used as feed, so it should be treated harmlessly to avoid environmental pollution and human health. The treatment of kitchen waste water should give consideration to the treatment effect, economy and easy operation.

Which stage is the sludge dewatering press used for kitchen waste water?

The kitchen waste water contains a large amount of leftovers. The common treatment method is to use a crusher to crush the large particles inside, and then enter the regulating tank. After being adjusted, the water will enter the air flotation machine. The water after being treated by the air flotation machine will enter the anaerobic and aerobic links. Through anaerobic and aerobic treatment, the organic matter in the sewage will be decomposed, and the sewage will enter the sedimentation tank, and then the sludge dewatering press will be used to realize the solid-liquid separation of sludge, Squeeze the sludge out of the sewage.

Advantages of sludge dewatering press:

1. The product specifications are diverse and the series are complete. For different processing scales, you can choose the appropriate model to avoid overuse.

2. The machine body is compact in design and integrated in concentration and dewatering. It is equipped with electric control cabinet, sludge flocculation mixing tank and other auxiliary devices, which are highly compatible with supporting equipment and easy to design.

3. The small design is convenient to adjust measures to local conditions, which can reduce the floor space and construction cost of the dehydrator itself.

4. It has the function of sludge thickening, so no thickening and storage unit is required to reduce the overall floor space and construction cost of sewage treatment facilities.

5. The main body has self-cleaning function, so it is not necessary to wash with large amount of water to prevent sludge blockage.

6. Low speed spiral extrusion technology, low power consumption.

7. The electric control cabinet is equipped with automatic control device to realize 24-hour automatic continuous unmanned operation from sludge conveying, liquid injection, thickening and dewatering to sludge cake discharge, and reduce labor costs.